Measurement Hardware

Sensors, signal conditioning, RASdelta measurement system (DAQ) including measurement boards for all relevant applications in the development and optimization of modern, efficient, and reliable powertrains: ROTEC measurement products enable users to seamlessly integrate a measurement chain from speed sensor to DAQ with an efficient measurement solution.

Experience the performance of our products firsthand and schedule a personalized consultation appointment.

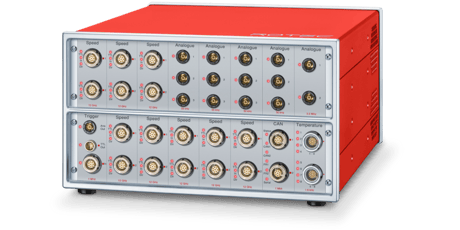

RASdelta Measurement System (DAQ)

The RASdelta measurement system is a modular, flexible, and highly precise data acquisition system (DAQ). The device is available in 8-slot and 16-slot variants and can be configured for individual measurement tasks in test stands and for dynamic measurements in vehicles.

In addition to its compact design, the system features a touch control panel, through which the RASdelta can also be configured as a data logger. Cascading of up to 6 RASdelta systems is easily possible via the second Ethernet interface.

The measurement system is configured by the user for the individual application case. For this purpose, the required measurement cards are selected from the catalog below.

-

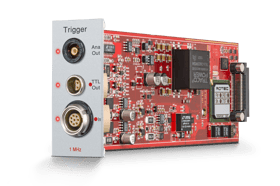

Click to view Trigger BoardTrigger Board

-

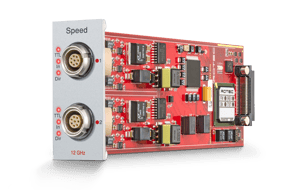

Click to view Speed BoardSpeed Board

-

Click to view Analog BoardsAnalog Boards

-

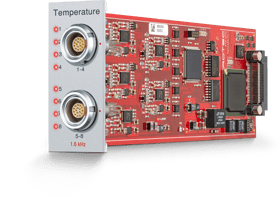

Click to view Temperature BoardTemperature Board

-

Click to view Strain Gauge BoardStrain Gauge Board

-

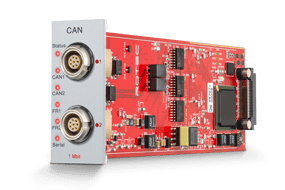

Click to view CAN-BUS BoardCAN-BUS Board

- Synchronizes all measuring cards, channels and cascaded systems

- 1x TTL trigger input with adjustable threshold values

- 2x TTL output for online monitoring

- Power supply for signal conditioning (DC 5 V and 12 V; 5 W)

The RASdelta Speed Board records precise multi-channel and digital speed measurement data for all transmission, control and auxiliary drive tests. It is therefore the basis for torsional vibration analysis. The data is recorded via magnetic, angle-equidistant scanning, an incremental encoder or a laser.

- 2-channel measuring card with 12.3 GHz counter clock (time resolution = 0.081 nanoseconds)

- Signal inputs for direction and reference pulse detection

- Adjustable values for trigger threshold and edge

- Operating modes: speed, frequency, duty cycle, on/off ratio

The RASdelta Analog Board measures analog variables such as airborne and structure-borne sound, acceleration, temperature, displacement or pressure. These variables can be used to determine the position of a sound source or to analyze the valve train or cylinder pressure. The analog measurement data is acquired by equidistant sampling.

- 2 analog voltage inputs, galvanically isolated

- AC and DC coupling, power supply for IEPE (ICP) sensors

- Adjustable voltage ranges for input signals

- 16 bit SigmaDelta ADC

- 3.2 MHz max. sampling rate for single-channel use

- 1.6 MHz max. sampling rate per channel for dual-channel operation

- 1.2 MHz analog bandwidth

- 3 analog voltage inputs, galvanically isolated

- AC and DC coupling, power supply for IEPE (ICP) sensors

- Adjustable voltage ranges for input signals

- 24 bit SigmaDelta ADC

- 50 kHz max. sampling rate per channel

- 24 kHz analog bandwidth

With the RASdelta temperature board, you record measurement data from resistance thermometers and thermocouples. The

measurement of the oil temperature in vehicles is indispensable, especially for transmission tests.

- 8-channel measurement board

- Maximum sampling rate: 1,6 kHz per channel (with 4-channel use)

- Measurement temperature range: -200°C - 850°C

- Supported sensors:

- Pt100/1000

- Thermocouple Type J (Fe/CuNi)

- Thermocouple Type K (NiCr/Ni)

- Thermocouple Type T (Cu/CuNi)

The RASdelta strain gauge board is an integrated dual-channel DC voltage amplifier for signal acquisition from strain gauge-based, piezoresistive, magnetoresistive or potentiometric transducers. These include force, torque, pressure, displacement and angle sensors or scales. The card does not require any additional measuring amplifiers.

- 2-channel measurement board

- Max. Sampling rate: 50 kHz per channel

- Supports full bridge and half bridge applications

- Adjustable bridge supply voltage: 1 V, 2.5 V, 5 V, 10 V

- Supports four-wire and six-wire configuration

- Automatic zero adjustment

- Detection of line interruptions/burn-out

The CAN-BUS board records CAN and OBD-II variables and evaluates them in relation to the torsional vibration analysis. This means that existing variables can be included in the measurement without the need for additional sensor applications. In addition to OBD II, Raw CAN and SAE J1939 protocol, it is possible to record FD CAN data directly via the measurement PC and separate third-party hardware.

- 2-channel measurement board

- Max. Baud rate: 1 Mbit/s per channel

- Adjustable post-sampling rate

- CAN standard 2.0 A (11-bit identifier) and 2.0 B (29-bit identifier); OBDII; J1939; (CAN-FD via PC USB connection)

- Modes: active/passive listener

- Adjustable BUS termination (120 Ohm)

Sensors

-

Click to view Differential sensorDifferential sensor

-

Click to view Laser sensorLaser sensor

-

Click to view GMR sensorGMR sensor

The magneto-resistive differential sensors from ROTEC are used for detecting rotational speeds on ferromagnetic gears and are available in various designs to suit the most demanding installation situations

TYPE A

- Two-part design - the preferred direction can be adjusted after sensor installation

- Suitable for standard temperature range -15°C to 100°C

- Optional with direction recognition (4-fold sensor)

TYPE B

- Short sensor length

- Standard temperature sensor (temperature range -15°C to 100°C) with detachable connection cable

- High-temperature sensor (temperature range -15°C to 160°C) with integrated cable, including adapter cable

TYPE C

- Angled 90° sensor head

- Standard temperature sensor (temperature range -15°C to 100°C) with detachable connection cable

- High-temperature sensor (temperature range -15°C to 160°C) with integrated cable, including adapter cable

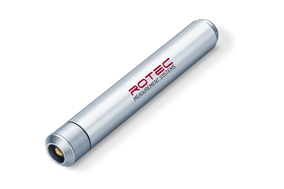

The ROTEC laser sensors are used for detecting rotational speeds by scanning a black-and-white (zebra) pattern. Both stripe tapes and stripe discs can be used. The stripe patterns are available in various standards. Handling of the butt joint when using stripe tapes is easily achievable through a correction mechanism in the RAS software.

Laser sensor (SeLas 4/5)

- Scanning of the object from the front or via a deflecting mirror at a 90° angle possible

- Fiber optic cables available with textile or metal sheathing

Zebra targets

- High-quality stripe patterns improve the quality of the speed signal

- Stripe tapes and stripe discs available in different standard dimensions

- Customized stripe patterns available upon request

The Sensitec sensor GLM711AVB is intended for the use with passive scales with a pitch of 1 mm. A bias magnet for the necessary magnetic fi eld and the sensor element is combined in a very small housing. The integration supports an optimal adjustment between sensor and magnet which helps to generate a very high quality of sensor signals.

Together with a ferromagnetic tooth structure, the sensor delivers two 90 degree phase shifted analog signals (sine and cosine).

The typical application area of the sensor is the measurement of valve lift curves during engine operation. Measurement of valve rotation is also possible.

Signal Conditioning / Electronics

-

Click to view Differential Sensor AdapterDifferential Sensor Adapter

-

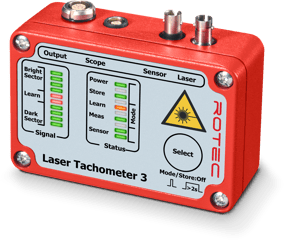

Click to view Laser TachometerLaser Tachometer

-

Click to view Rotary Encoder AdapterRotary Encoder Adapter

-

Click to view 4-fold Sensor4-fold Sensor

-

Click to view Encoder Phase ShifterEncoder Phase Shifter

-

Click to view GMR Sensor AdapterGMR Sensor Adapter

-

Click to view Valve lift measurement moduleValve lift measurement module

The Differential Sensor Adapter (DSA) converts the sinusoidal signal of the ROTEC magnetic sensor into a pulse sequence of needle pulses with TTL level, which is processed by the RASdelta speed measurement card.

An LED display facilitates optimal setup of the differential sensor in relation to the gearing, to achieve the best possible signal quality.

The Inline TTL Digitizer (Inline-DSA) is the compact version of the ROTEC Differential Sensor Adapter (DSA) and is particularly suitable for mobile use. The electronics convert the sinusoidal signal from the ROTEC magnetic sensor into a TTL pulse sequence, which is processed by the RASdelta speed measurement card.

ROTEC Laser Tachometer 3 (ELLAS3) is used for optical speed measurement. The electronics generate a power-regulated laser light, which is transmitted by the ROTEC laser sensor to a black-and-white stripe pattern attached to the object being measured. The light-dark transitions of the measurement object are scanned using the reflection method. This results in a pulse train with TTL level, which is processed by the RASdelta speed measurement card.

The Rotary Encoder Adapter (ELDGADP2) is used for capturing TTL or SIN/COS rotary encoder signals.

The electronics generate a digital pulse train with TTL level from the signals of the incremental encoder. The Rotary Encoder Adapter captures the encoder signals in forward and reverse directions and derives direction information from them. The signals for speed and direction, as well as the reference pulse, are captured and processed by the RASdelta speed measurement card.

Additionally, the reference pulse can be tapped at a separate socket and used as a start trigger for measurements.

The Inline DGADP is the compact version of the ROTEC Rotary Encoder Adapter and is particularly suitable for mobile use. Additionally, the adapter is available in two variants: for TTL and for HTL incremental encoders.

The electronics generate a digital pulse train with TTL level from the signals of the incremental encoder, which serves as the measurement signal. The Inline DGADP captures the encoder signals in forward and reverse directions and derives direction information from them.

The electronics for direction detection (EL4FP) convert the sinusoidal signal from the ROTEC magnetic sensor into a pulse train of needle pulses with TTL level. When using the ROTEC 4-channel magnetic sensor, the direction information can be derived and transferred to the RASdelta speed measurement card.

The ROTEC Phase Shifter is used in conjunction with the ROTEC Rotary Encoder Adapter. The Phase Shifter delays the reference signal of an encoder by an adjustable number of speed pulses (=increments). The original reference mark is suppressed and replaced by a synthetically generated mark. This synthetic reference pulse can be separately tapped and used as a start trigger for measurements.

The GMR Sensor Adapter (ELGMR) is suitable for valve lift measurements with the GLM711AVB GMR sensor. The electronics serve to amplify the captured raw signals and ensure a noise-free signal as well as sufficient bandwidth.

The amplified sensor signals are outputted via separate sine and cosine outputs and can be recorded with the 3.2 MHz RASdelta analog measurement card.

The Valve Train Measurement Module (ELVTMM, formerly Sensitec SPP3001) serves as an evaluation unit for measurements on the valve train. The electronics condition the sensor signal and calculate an online valve lift with an accuracy of +/- 10 μm, which is provided at the BNC connector as an output voltage between 0-10 V. The module is available in 2- and 4-channel variants.

For further processing of the valve lift signal, the ROTEC RAS software package "Valve Train Analysis" offers in-depth dynamic analysis capabilities.