Measurement solutions

The basis of ROTEC measurement and evaluation solutions lies in the reliable measurement of rotational speeds and angular positions, as well as the detection of valve lift. What sets us apart is the individual signal chain for each sensor type, guaranteeing users the highest signal quality and excellent user-friendliness. For applications such as magnetic speed sensing on gears, optical speed sensing on black and white patterns, and valve lift measurements on tooth structures, Rotec sensor solutions offer users the highest quality with simultaneously high flexibility for individual solutions. Feel free to contact us for personal consultation.

Any more questions?

What does the ROTEC solution for rotation analysis look like and what does RAS mean?

The ROTEC Rotational Analysis System (RAS) has been used for more than 30 years by users in the mechanical engineering, automotive, power generation and motorsport industries for the comprehensive analysis of rotating components.

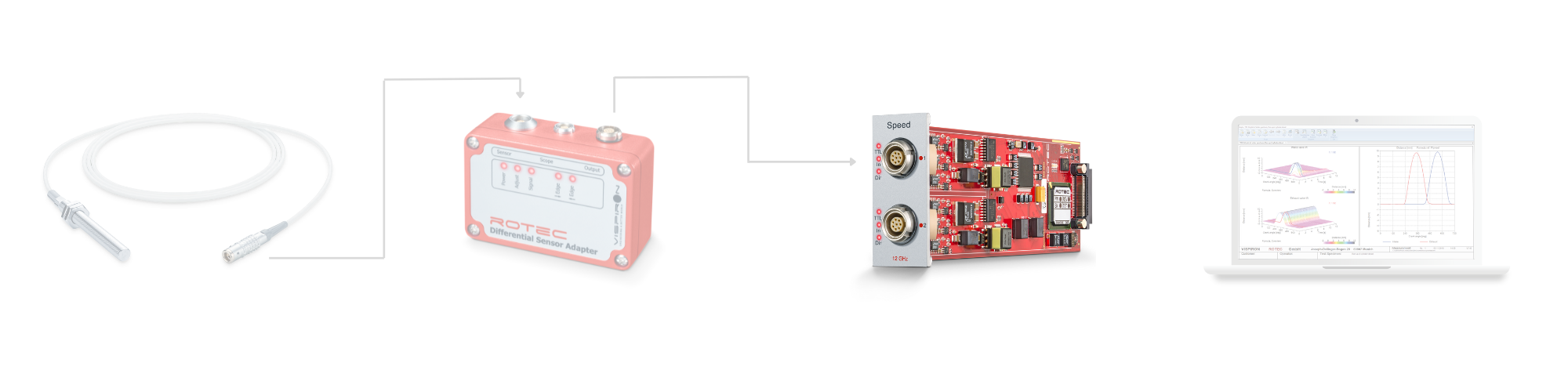

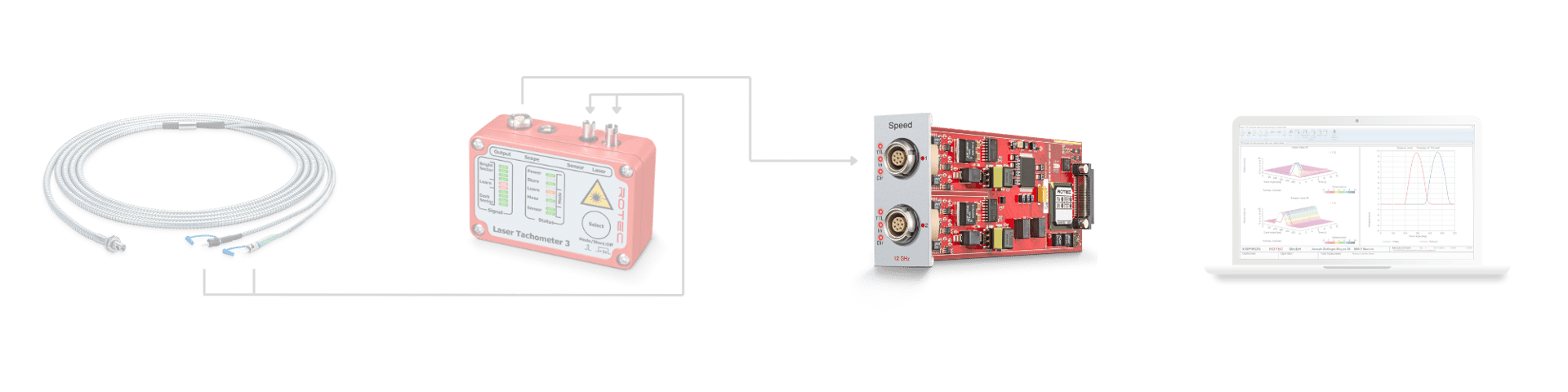

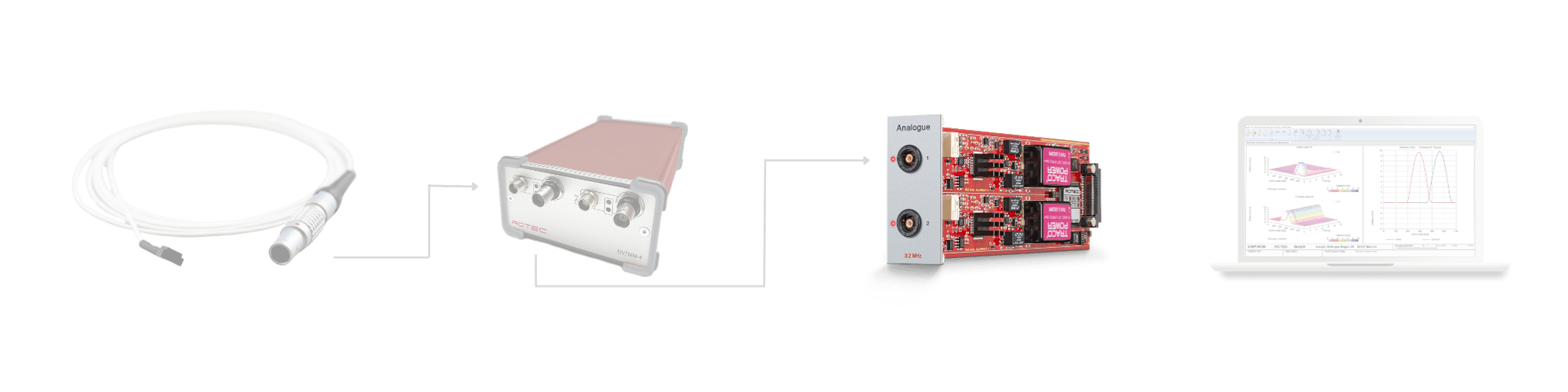

With its unique measurement method using a 12.3 GHz counter card and a strictly angle-based approach to rotational speed detection and analysis, the RAS system offers users an unparalleled advantage.

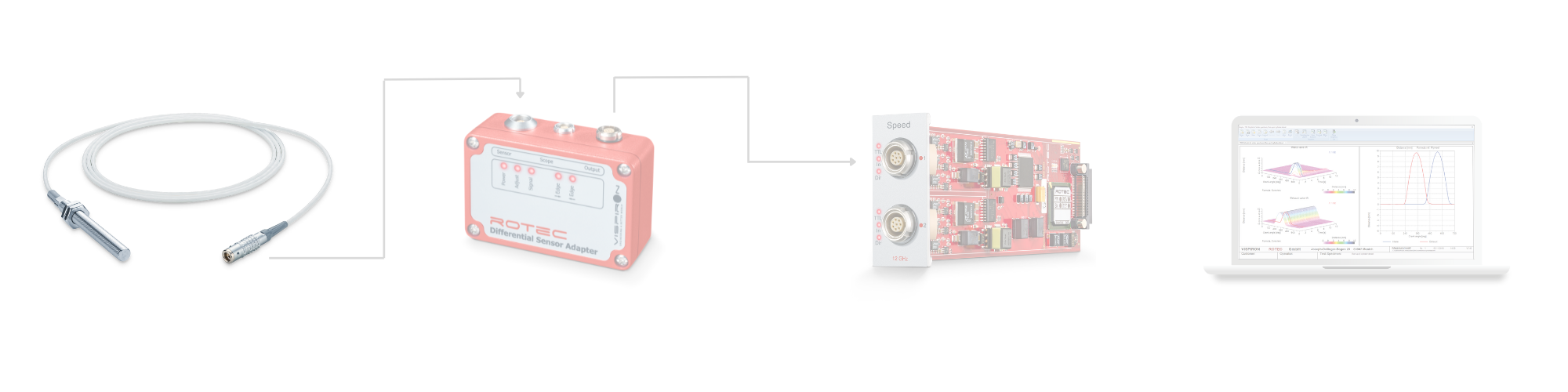

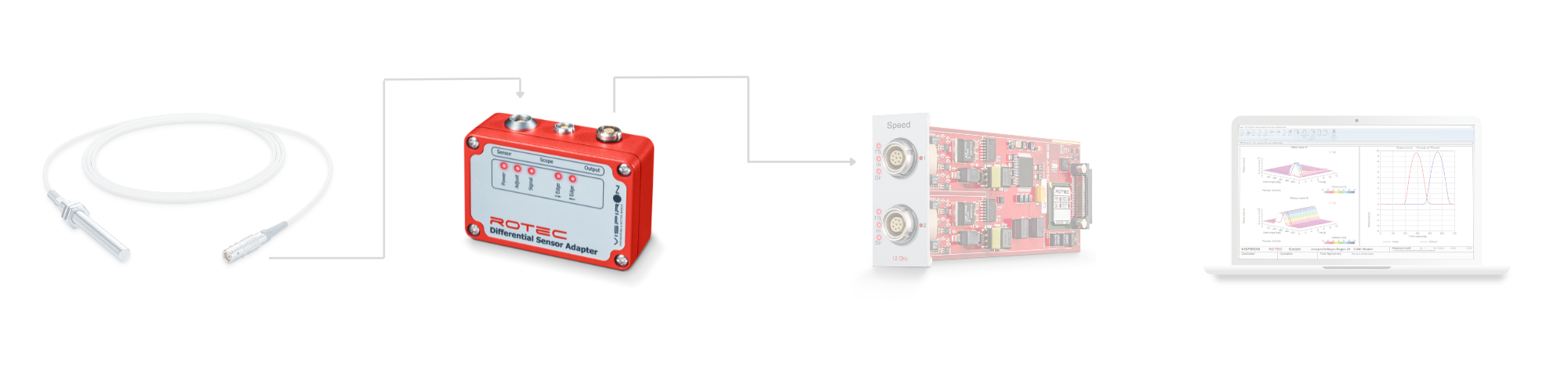

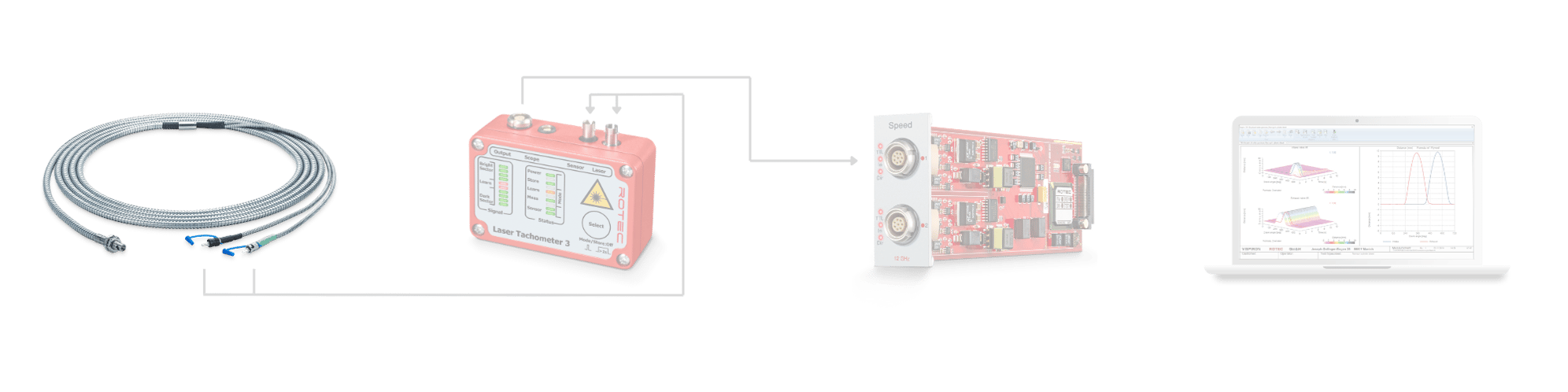

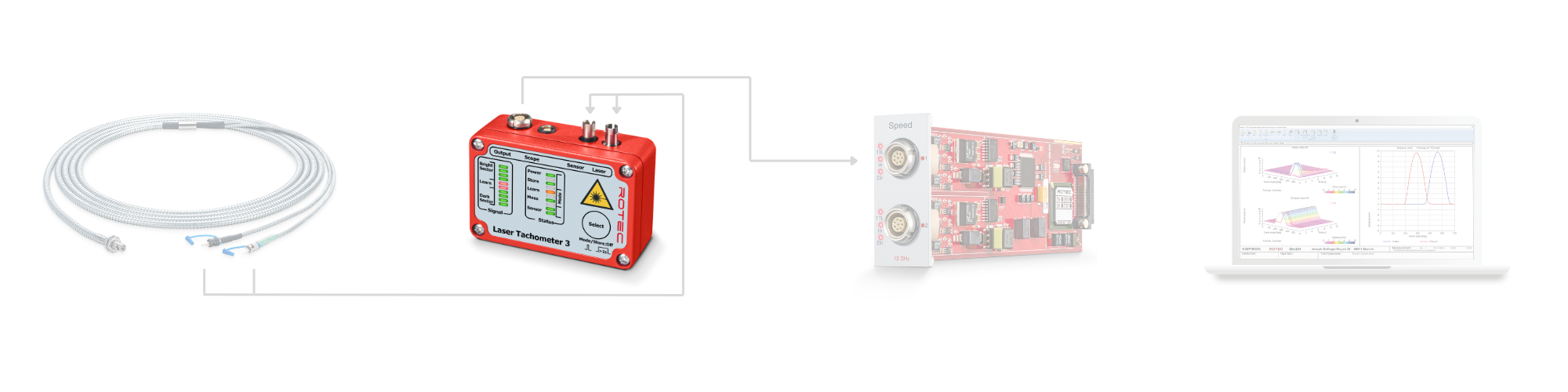

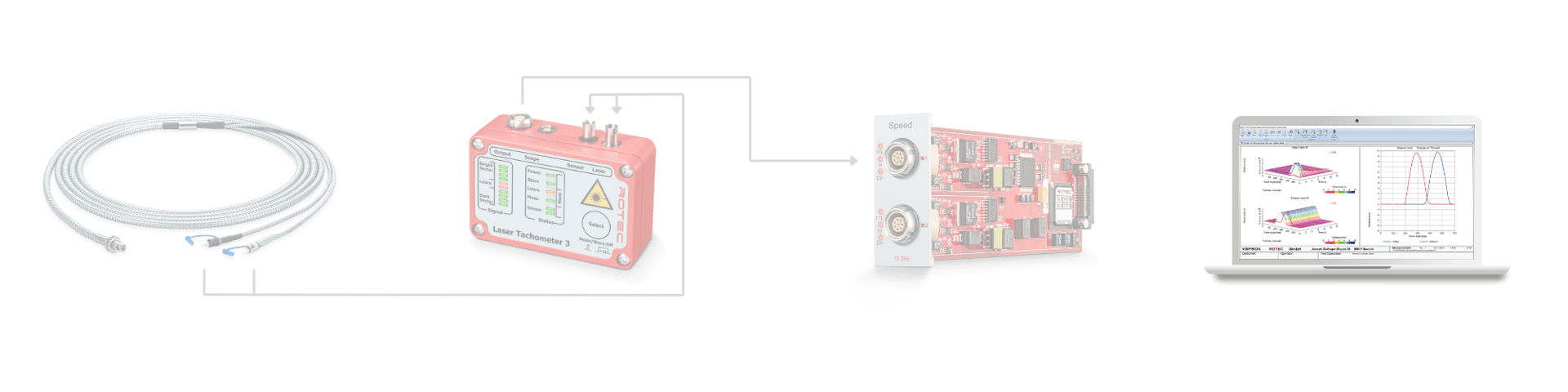

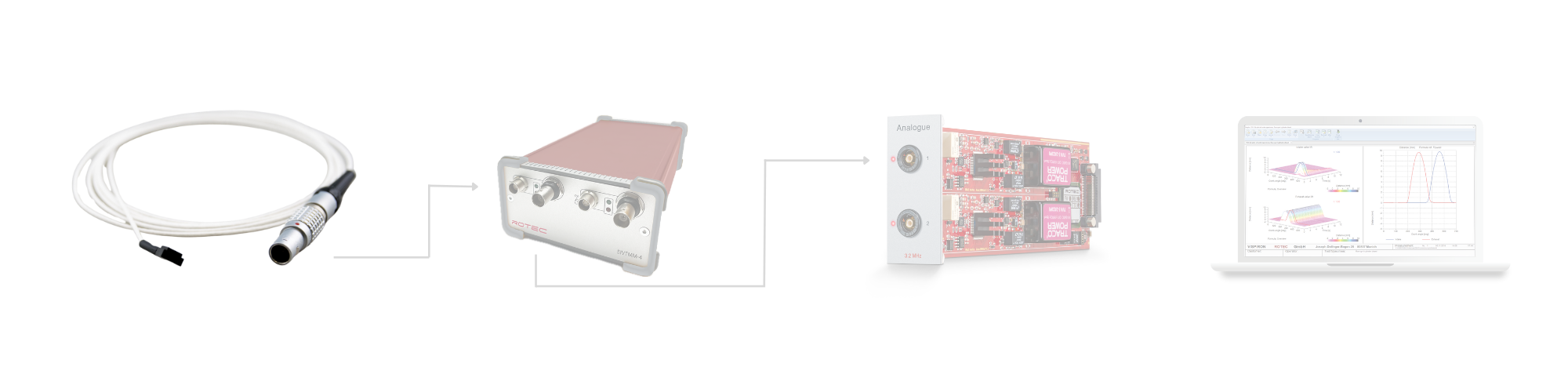

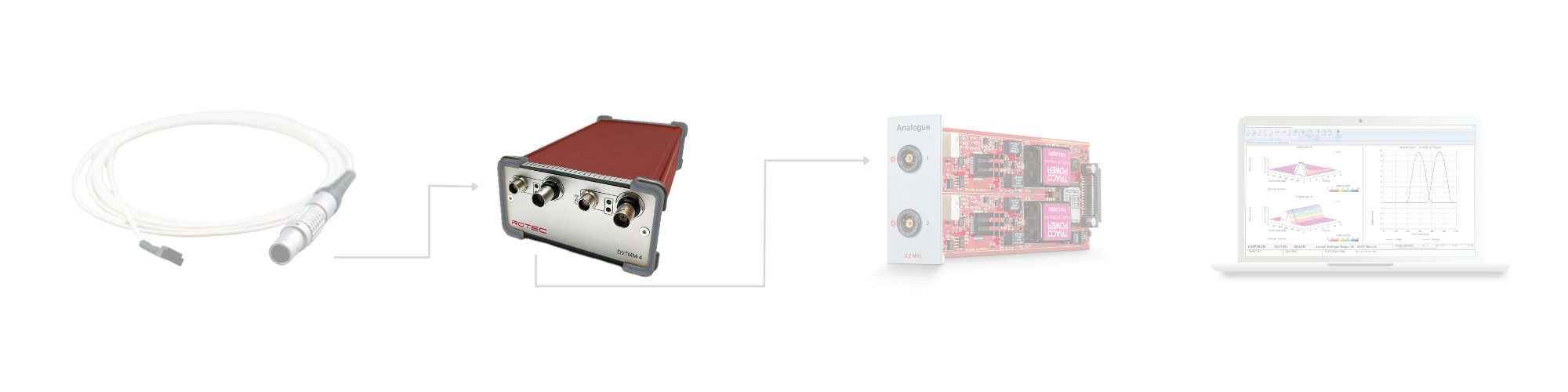

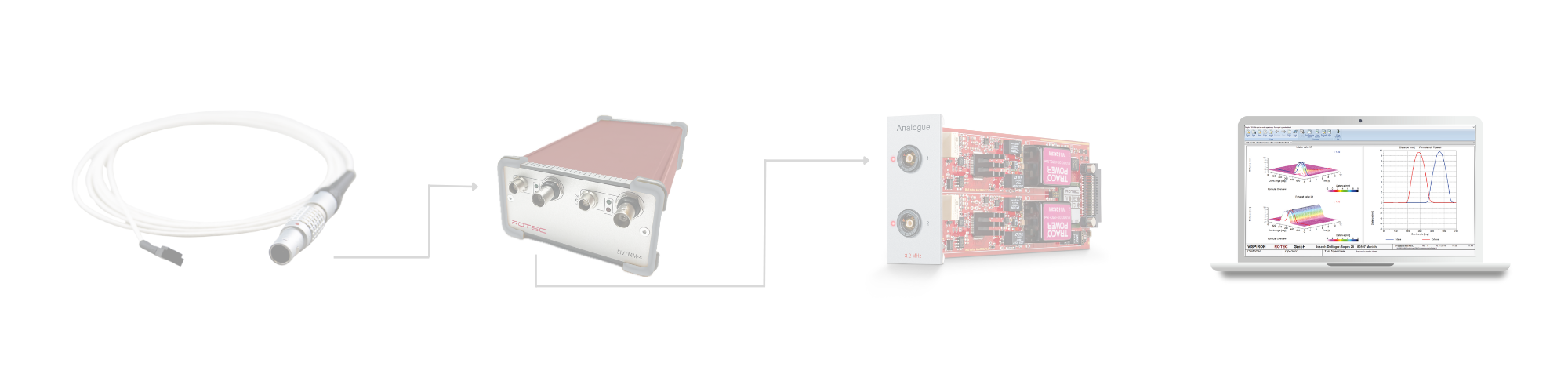

ROTEC offers not only optical and magnetic speed sensors including signal conditioning adapters, but also the modular measuring system RASdelta as well as specialized and user-friendly software for measurement and analysis. This enables a complete solution from a single source. The ROTEC measurement technology products are perfectly matched to each other and deliver meaningful results within a very short time after the uncomplicated setup of the measurement chain.

Thanks to the angle-based approach to speed measurement, problems such as sensor vibrations can be detected after the first measurement and rectified immediately. This effectively prevents costly incorrect measurements.

Our team of experts at ROTEC ENGINEERING, consisting of long-standing users, will be happy to assist you with challenging tasks.

Are there options for customizing the measurement systems and software?

The ROTEC RASdelta front end is a versatile modular measurement system that can be individually configured with 8 or 16 measurement cards to meet your specific measurement requirements.

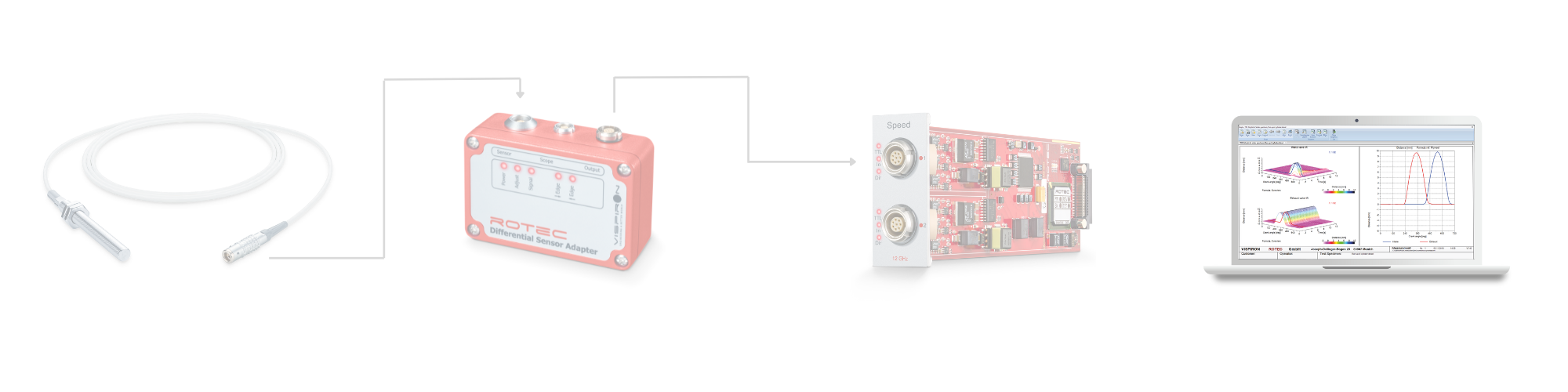

Our RAS software offers you a comprehensive modular system for analyzing rotating components and complex systems. It is an effective tool for machine builders and requires no programming knowledge to carry out measurements or perform evaluations.

If you have specific metrological questions, our experienced ROTEC ENGINEERING consulting team will be happy to support you.

Does ROTEC offer other services in addition to the measuring systems, e.g. individual consulting or project support?

ROTEC offers not only speed sensors, signal conditioning, measurement systems (DAQ) and measurement and evaluation software, but also engineering and consulting services.

Our services include the design of measuring points in CAD, the mechanical processing of components, the application and calibration of sensors, the execution of measurement tasks and the evaluation of measurements in accordance with our customers' requirements, including the presentation of the results. The ROTEC ENGINEERING team can also implement sub-projects as part of project support.

Is there training or technical support for commissioning and integrating the measuring systems?

In addition to our annual ROTEC Training Week, which is held in both German and English, we also offer customized training courses for users. These training courses are specially tailored to your individual application of the ROTEC measuring system and include not only the theoretical basics and a detailed presentation of the software, but also practical demo measurements in your environment. This ensures that future users are optimally prepared for your specific application.

Furthermore, we are happy to support you in the commissioning of new measuring systems to enable you to become familiar with the settings and possibilities of the RAS software as quickly as possible.

How is support ensured and are there self-help options?

In addition to our sales and support team in Munich, which serves the Central European market directly from here, ROTEC also cooperates with local partners in many global markets. These partners support local users with trained personnel for all matters relating to ROTEC measurement technology, first-level support and sales inquiries.

Our customers around the world appreciate the proximity of our sales and support teams, as this enables us to guarantee effective support even for short-term questions.

In addition to personal contact, ROTEC also offers an extensive knowledge database for self-help. Please register for our knowledge database to obtain detailed information on measuring and evaluating torsional vibrations, transmission errors and valve systems, among other things.