Mechanical Engineering

-

Click to view Single flank rolling testSingle flank rolling test

-

Click to view Rolling element gearsRolling element gears

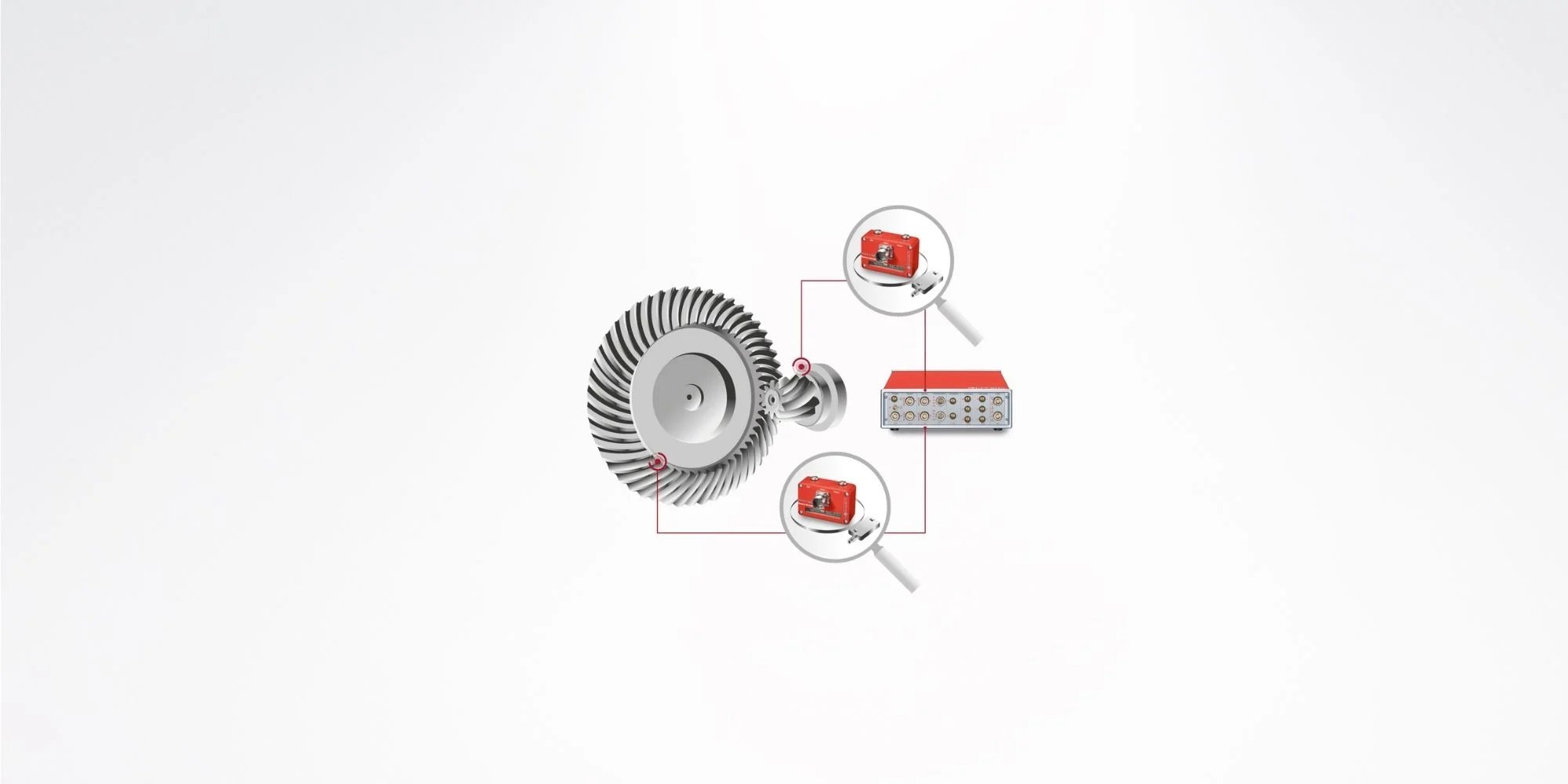

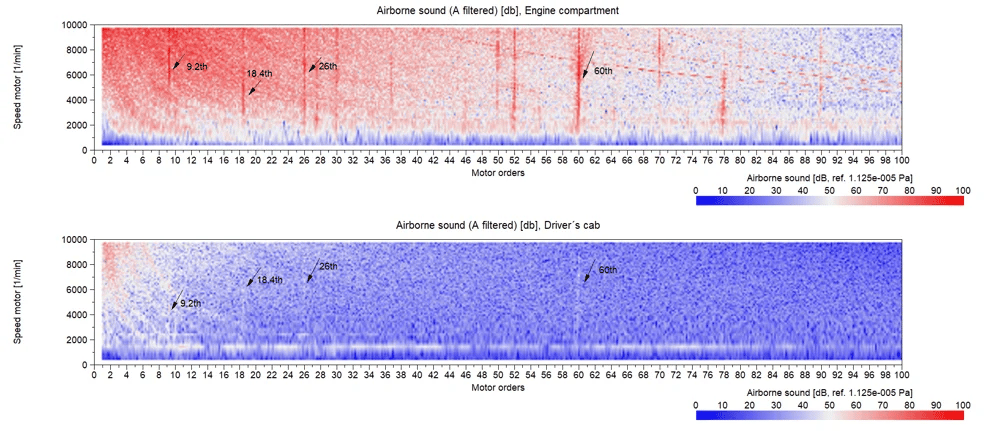

Problem: noise behavior of the gearbox

Goal: Testing the gear quality

The single flank rolling test is a test method used to measure the rolling deviation on a bevel gear. The aim is to check the gear quality and detect faulty gears. The measurement itself takes place under quasi-static conditions and is intended to exclude dynamic effects. High-resolution encoders are attached to the pinion and ring wheel sides and tested at low speeds of up to 60 1/min and loads of up to 20 Nm. The two pairs of gears are rolled onto each other until each tooth has made contact with each tooth of the counter gear. This means that any deviation in the translation that is based on geometric deviations is recorded. The recorded measured values are evaluated in the time and spectral range. The measurement results are averaged over one revolution. The evaluation in the time domain can separate long-wave and short-wave components. This means that macro- and micro-geometric errors of the gear pair can be displayed separately.

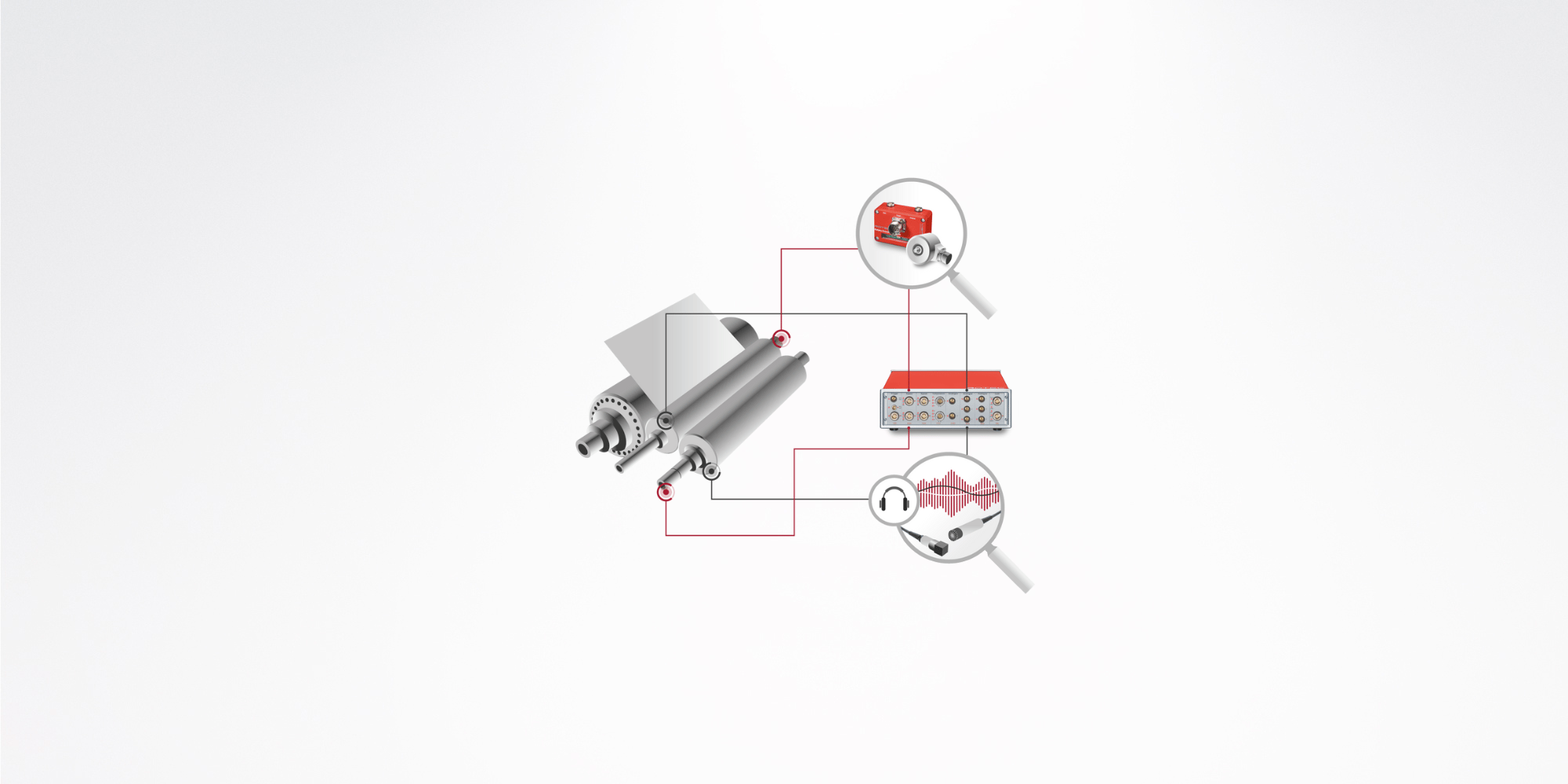

Problem: Disruptions in production

Goal: Reliable design of the gearbox

Vibrations in paper machine gears can affect paper quality and lead to frequent breaks in the paper conveyor. Such rotational energies arise in the rolling element gear, in which rollers and cylinders (rolling elements) are combined. The transmission of torque and movement is based on the principle of frictional engagement. Particularly when rolling elements are used to guide material, they must transmit a rotational movement that is as uniform as possible in order to ensure precise positioning of the material to be guided and roller parallelism. This is also the case with printing machines, where ink is applied to a material in several layers.

Torsional vibrations can also correlate with the torque signal. To analyze this, the speed is recorded using a rotary encoder on the input and output shafts. The structure-borne noise signals are recorded using an acceleration sensor on the roller housing. Finally, the measured values recorded in the time and spectral range are evaluated and the acoustic behavior is analyzed.

The recorded measured values are evaluated in the time and spectral domain. At the same time, the acoustic behavior is analyzed.

ROTEC ENGINEERING also supports you with technical engineering knowledge on problems relating to vibration analyzes on engines, transmissions and drive trains. With our know-how, we make a valuable contribution to your product in the areas of timing train validation, valve train optimization, clutch design, transmission errors (TE), transmission and oil balance optimization, drive train measurement and optimization, current and voltage analysis as well as the application of measurement technology.

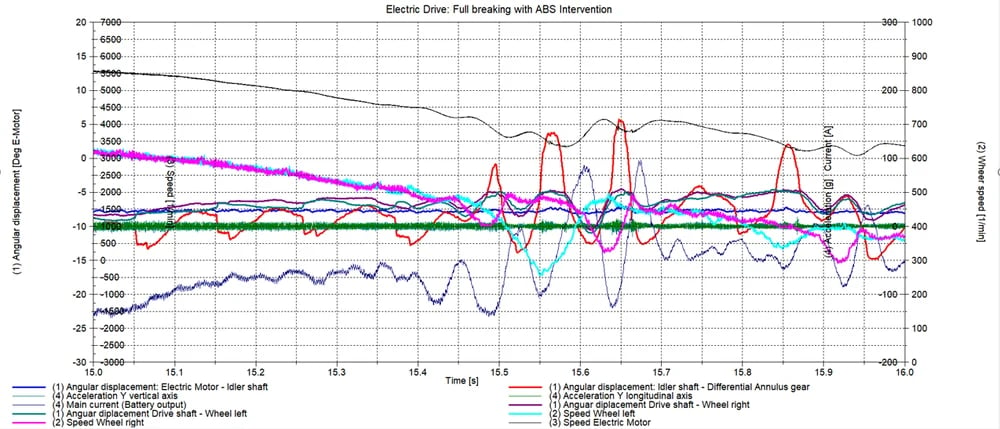

Analyzes in the time domain

- Dynamic twist angle in the transmission components

- Analysis of shaft torsion

- Sudden loads during load changes

- Analysis of the stiffness in the drive

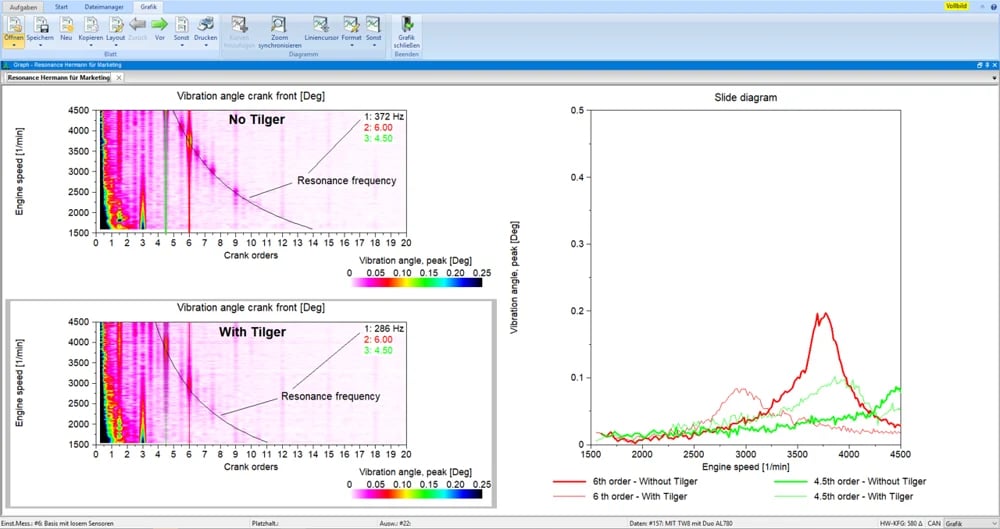

Analyzes in the spectral range

- Analysis of the dynamic suggestions

- Checking the vibration dampers and coupling systems

- Resonance behavior of the entire system

- Change in natural frequencies over ambient conditions

- Dynamic peak loads

Analysis of acoustic behavior

- Identification of noise sources

- Detection of component resonances

- Specialized software solution for transmission examinations

Any more questions?

What does the ROTEC solution for rotation analysis look like and what does RAS mean?

The ROTEC Rotational Analysis System (RAS) has been used for more than 30 years by users in the mechanical engineering, automotive, power generation and motorsport industries for the comprehensive analysis of rotating components.

With its unique measurement method using a 12.3 GHz counter card and a strictly angle-based approach to rotational speed detection and analysis, the RAS system offers users an unparalleled advantage.

ROTEC offers not only optical and magnetic speed sensors including signal conditioning adapters, but also the modular measuring system RASdelta as well as specialized and user-friendly software for measurement and analysis. This enables a complete solution from a single source. The ROTEC measurement technology products are perfectly matched to each other and deliver meaningful results within a very short time after the uncomplicated setup of the measurement chain.

Thanks to the angle-based approach to speed measurement, problems such as sensor vibrations can be detected after the first measurement and rectified immediately. This effectively prevents costly incorrect measurements.

Our team of experts at ROTEC ENGINEERING, consisting of long-standing users, will be happy to assist you with challenging tasks.

Are there options for customizing the measurement systems and software?

The ROTEC RASdelta front end is a versatile modular measurement system that can be individually configured with 8 or 16 measurement cards to meet your specific measurement requirements.

Our RAS software offers you a comprehensive modular system for analyzing rotating components and complex systems. It is an effective tool for machine builders and requires no programming knowledge to carry out measurements or perform evaluations.

If you have specific metrological questions, our experienced ROTEC ENGINEERING consulting team will be happy to support you.

Does ROTEC offer other services in addition to the measuring systems, e.g. individual consulting or project support?

ROTEC offers not only speed sensors, signal conditioning, measurement systems (DAQ) and measurement and evaluation software, but also engineering and consulting services.

Our services include the design of measuring points in CAD, the mechanical processing of components, the application and calibration of sensors, the execution of measurement tasks and the evaluation of measurements in accordance with our customers' requirements, including the presentation of the results. The ROTEC ENGINEERING team can also implement sub-projects as part of project support.

Is there training or technical support for commissioning and integrating the measuring systems?

In addition to our annual ROTEC Training Week, which is held in both German and English, we also offer customized training courses for users. These training courses are specially tailored to your individual application of the ROTEC measuring system and include not only the theoretical basics and a detailed presentation of the software, but also practical demo measurements in your environment. This ensures that future users are optimally prepared for your specific application.

Furthermore, we are happy to support you in the commissioning of new measuring systems to enable you to become familiar with the settings and possibilities of the RAS software as quickly as possible.

How is support ensured and are there self-help options?

In addition to our sales and support team in Munich, which serves the Central European market directly from here, ROTEC also cooperates with local partners in many global markets. These partners support local users with trained personnel for all matters relating to ROTEC measurement technology, first-level support and sales inquiries.

Our customers around the world appreciate the proximity of our sales and support teams, as this enables us to guarantee effective support even for short-term questions.

In addition to personal contact, ROTEC also offers an extensive knowledge database for self-help. Please register for our knowledge database to obtain detailed information on measuring and evaluating torsional vibrations, transmission errors and valve systems, among other things.